Monocalcium phosphate is a raising agent commonly found in baking powder and used as an ingredient in various bakery items. Monocalcium Phosphate is available in two forms: monohydrate and anhydrous salts. The monohydrate is comparatively fast-acting, and it is typically used in combination with slower-acting leavening agents. It releases leavening gas from baking soda during mixing, which allows it to achieve a fine, uniform grain in the baked product as long as a slower-acting leavener is also present. The anhydrous form is coated with a slowly dissolving phosphate material that delays its reaction with baking soda. This form is typically used in home baking applications.

What is Monocalcium Phosphate?

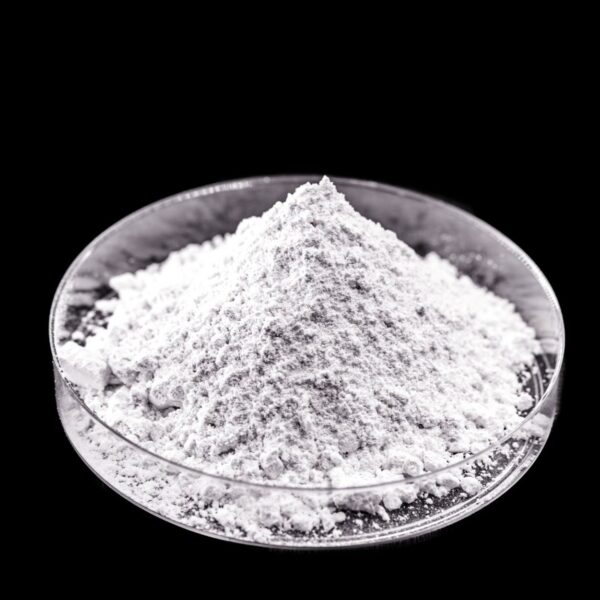

Monocalcium phosphate has a chemical formula of CaH4P2O8. Both salts of monocalcium phosphate are colorless solids. When monocalcium phosphate is used as a component in a ready-made baking powder, the acid and alkali ingredients are included in the proportions such that they will exactly neutralize each other and not significantly affect the overall pH of the product. Monocalcium phosphate is soluble in hydrochloric acid and nitric acid and is slightly soluble in cold water. It is almost insoluble in ethanol.

Source: Wikipedia

How is Monocalcium Phosphate Produced?

Monocalcium Phosphate is produced from natural mineral substances. In food industry applications, it is produced by partially neutralizing phosphoric acid with calcium hydroxide, followed by water evaporation at low temperatures in acidic conditions. Food-grade phosphoric acid is made from phosphate rocks, which are mined, refined, and purified. Companies that make phosphoric acid in the U.S., Europe, and several other countries follow strict procedures to ensure purity.

Use of Monocalcium Phosphate in the Food Industry

The primary use of monocalcium phosphate in the food industry is leavening in bakery products. It helps various bakery goods to rise due to the release of carbon dioxide, resulting in light, fluffy products. It is also used in some powdered beverage products and convenience foods.

Product Examples

| Type | Examples |

| Bakery | Pancakes, Cookies, Breads, Angel Food Cake |

| Powdered Beverage | Energy Drink Powder, Malted Milk Powder |

| Convenience Food | Canned Meals |

Properties of Monocalcium Phosphate

| Chemical Formula | NaH2PO4 |

| Molar Mass | 119.98 g/mol |

| Appearance | White powder or crystals |

| Density | 2.36 g/cm3 (anhydrous) |

| Solubility in Water | 59.90 g/100 mL (0°C) |

Typical Formulations

Baked Dough

Here is an example of a baked dough formulation table with monocalcium phosphate, along with the composition of ingredients:

| Ingredients | Composition (grams) |

| Flour | 552 |

| Water | 314 |

| Yeast | 19 |

| Yeast Food | 4 |

| Monocalcium Phosphate | 2 |

| Dough Flour | 298 |

| Sugar | 42.5 |

| NFDM or Substitute | 17 |

| Shortening | 13 |

| Monoglycerides | 4 |

Source: Google Patents

Monocalcium Phosphate Formulation Considerations

Stability

Monocalcium phosphate is stable at a pH range lower than 2. Anhydrous monocalcium phosphate is stable up to 80℃.

Effect on taste & texture of food products

Leavening agents significantly affect the structure and texture of final bakery products due to the release of CO₂. When combined with other slow-acting leavening agents, monocalcium phosphate helps to achieve a fine, uniform grain in baked goods. Monocalcium phosphate can leave a slightly bitter, astringent taste in final food products, so optimizing the dosage for various bakery goods is extremely important.

Dosage

When monocalcium phosphate is used in phosphated flour, the recommended dosage level is 0.25–0.75% of the weight of the finished flour. When used in self-rising flours, the recommended dosage should not exceed 4.5% based on flour weight.

Safety & Regulatory Considerations

| FDA Information | Monocalcium phosphate is approved by the FDA for use as a food additive when used in accordance with good manufacturing practices. It is Generally Recognised as Safe (GRAS) per Part 182, Subpart B – Multiple Purpose GRAS Food Substances. According to Sec. 137.175, monocalcium phosphate levels in flour should be between 0.25-0.75% of the weight of the finished phosphated flour. In determining whether the ash content complies with the requirements of this section, allowance is made for added monocalcium phosphate. |

| EU Information | Calcium phosphates, food additives E341 (I,II, and III) are listed in Commission Regulation (EU) No 231/2012 as authorized food additives and classified as “other additives than colors and sweeteners.” |

Identification Numbers

| Chemical Name | Calcium dihydrogen phosphate |

| CAS Number | 7758-23-8 |

| REACH Registration Number | A registration number is unavailable for this substance as the substance or its uses are exempted from registration, the annual tonnage does not require registration, or the registration is envisaged for a later registration deadline. |

| EC Number | 231-837-1 |

| INS No. (Food Additive) | 341(i) |

| CA Index Name | Calcium Phosphate Monobasic |

Fun Facts About Monocalcium Phosphate

- Monocalcium phosphate is often used in toothpaste formulations as an abrasive agent that helps remove plaque and stains from teeth. It also contributes to the creamy texture of the toothpaste.

- In agriculture, monocalcium phosphate is utilized as a fertilizer. It provides both calcium and phosphorus to plants, essential nutrients for growth. Additionally, it can help regulate soil pH, creating a more favorable environment for plant uptake of nutrients.

Additional Resources

- ScienceDirect Topics: Monocalcium Phosphate

- ChemBK: Monocalcium Phosphate

- Wikipedia: Monocalcium Phosphate (Image)

- Food Ingredient Facts: Monocalcium Phosphate

- Future Market Insights: Monocalcium Phosphate Market

- Bakerpedia: Monocalcium Phosphate (MCP)

- Google Patents: US3529970

- Jimdo Storage: Referenz MSc Durni (PDF)

- FDA: CFR – Code of Federal Regulations Title 21, § 182.1217

- FDA: CFR – Code of Federal Regulations Title 21, § 137.175