Stearates are used in the food industry as anticaking agents, lubricants, emulsifiers, binders, and release agents. Calcium stearate and magnesium stearate are solid-phase lubricants that reduce friction between particles of the substance to which it is added. They are available in powder, ground, or beaded form. Stearates are also commonly used as inactive ingredients or excipients in producing pharmaceutical and nutraceutical tablets, capsules, and powders.

What are Stearates?

Stearates are naturally occurring saturated fatty acids in the glycerides of animal fats and most vegetable oils. It is derived from palm oil, soybean oil, or edible tallow. When exposed to heat, stearates slowly degrade to form stearic acid.

Calcium stearate is a white to yellowish waxy powder. It has a greasy feel and a characteristic fatty odor. Calcium stearate is only slightly soluble in water, unlike sodium and potassium stearate, which are both highly water-soluble. Divalent Ca2+ can bind two non-polar fatty acid molecules, while Na+ and K+ can only bind to one fatty acid as a monovalent ion. Two fatty acid molecules prevent Ca2+ from interacting with water molecules, thus making it insoluble in water. Calcium stearate is made up of two stearate anions and a calcium cation.

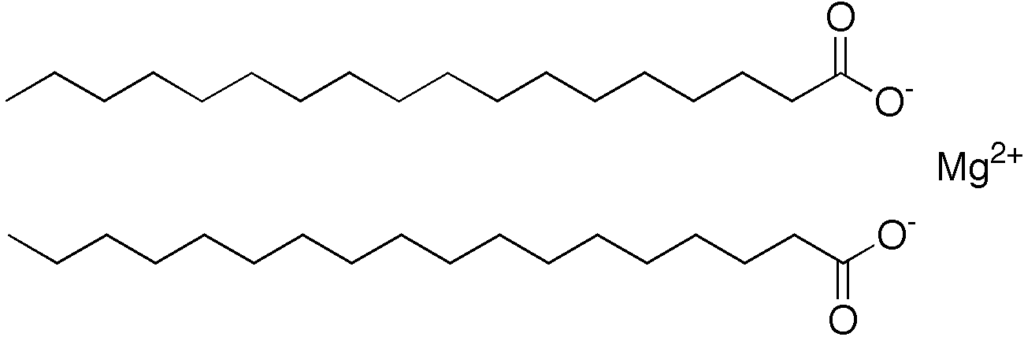

Magnesium stearate is available as a white or yellowish powder or brittle solid and has a distinctive odor. It is soluble in organic solvents, such as ethanol and toluene.

Source: Wikipedia

Source: Wikipedia

Applications in Food and Nutrition

Applications in Food

| Function | Applications |

| Lubricant | Stearates can be used as a lubricant to prevent ingredients from sticking or binding to one another or equipment. This lubricative property can help improve the efficiency of manufacturing, packaging, and material handling. |

| Release Agent | When used as a release agent, stearates create a thin layer on the surface of food products, preventing them from sticking to molds, pans, or other surfaces during processing or packaging. |

| Emulsifier | In some food products, calcium stearate can act as an emulsifier, helping to mix and stabilize ingredients that generally separate, such as oil and water. This can improve the texture and mouthfeel of the product. |

| Stabilizer | Calcium stearate stabilizes certain food products, helping maintain the desired texture and preventing ingredient separation or breakdown. It can improve the shelf life and overall quality of the product. |

| Dough Conditioner | Stearates can be used as free-flowing agents with dough softeners such as mono- and di-glycerides. |

Application in Nutraceuticals

| Tablet Coating Agent | Stearates provide lubrication to a tablet and alter the disintegration rate, affecting the delivery of the active. |

Product Examples

| Type | Examples |

| Convenience | Ready premixes, powdered beverages, powder mixes |

| Spice, Salt & Condiments | Spice mixes, seasonings, salt mixes |

| Tabletop Sweeteners | Sugar, non-nutritive sweetener mixes |

| Snacks | Snacks |

| Dietary Supplements | Granules, pellets premix, chewable tablets, effervescent tablets, lozenges |

Properties of Stearates

| Magnesium Stearate | Calcium Stearate | |

| Physical Form | Powder, granules, crystals | Powder, granules, crystals |

| Color | White to yellowish white | White to yellowish white |

| Odor | Distinctive fatty odor | Distinctive fatty odor |

| Storage Temperature & Conditions | 15-25°C, store in a cool, well-ventilated place | 15-25°C, store in a cool, well-ventilated place |

| Molecular Weight | 571.27 | 607.02 |

| Appearance | White to yellowish-white waxy powder or dispersions | White to yellowish-white waxy powder or dispersions |

| Melting Point | 155°C | 179-180°C |

| Boiling Point | 359.4°C | 661.06°C |

| Bulk Density | 0.159 g/cm3 | 0.32 g/cm3 |

| Solubility | 4 mg/ 100 ml @25°C | ≤2 mg/L @ 35°C |

Typical Formulations

Dried Honey Tablet

Here is an example formulation table for a dried honey tablet with magnesium stearate:

| Ingredient | Composition |

| Honey powder & gelatinized starch | 280 pounds |

| Non-fat dried milk | 10 pounds |

| Distilled water | 2 gallons |

| Isopropyl alcohol | 2 gallons |

| Magnesium stearate | 1500 g |

| Vitamin E | 8-9 grams |

Source: Google Patents

Probiotic Tablet

Here is an example formulation table for a probiotic tablet with magnesium stearate:

| Ingredient | Composition (mg/tablet) |

| L.acidophilus | 50 |

| Pharmaburst (carrier) | 539.3 |

| Sucralose | 0.9 |

| Natural/artificial flavor | 0.6 |

| FD&C colorant | 1.2 |

| Magnesium stearate | 8.0 |

Source: Google Patents

Sea Buckthorn Yogurt Slices

Here is an example formulation table for sea buckthorn yogurt slices with magnesium stearate:

| Ingredient | Composition (% Juice milk mix basis) |

| Sea buckthorn juice: Milk | 1:3 |

| Whole milk powder | 2 |

| Granulated sugar | 6 |

| Magnesium stearate | 1.5 |

| Maltodextrin | 15 |

| Citric acid | 0.1 |

| Sodium CMC | 0.2 |

Source: Google Patents

Stearates Formulation Considerations

Dosage

The dosage of stearates varies from 0.5-5%, depending on the intended application and effect on the final product.

Lubrication Mechanism

When used in powders, lubrication typically involves water and/or gas molecules entering the spaces of the crystal lattice, causing a decrease in the interactive forces of the crystal lattice. This, in turn, leads to easier shearing of the lubricant powder particles.

In powders and solids, the lubrication action depends on the disintegration of lubricant particles. Small lubricant particles disperse large particles and disintegrate when shear stress affects the system. The lubricant powder deteriorates, leading to a decrease in friction force.

Magnesium stearate has four pseudo polymorphs: anhydrate, monohydrate, dihydrate, and trihydrate. The type of hydrate form can significantly affect the powder properties, including lubrication.

Factors Affecting the Lubrication Properties of Stearates

A range of factors can affect the lubrication properties of stearates, as described in the table below:

| Moisture Content | In a study, a reduction in moisture content due to drying led to a decrease in lubricating properties. |

| Total Enthalpy | Enthalpy was reported to have a greater effect on lubrication properties. |

| Particle Size & Surface Area | In a study, milling decreased the particle size and increased the specific surface area. Smaller particle sizes and larger specific surface areas had considerably better lubricity. |

| Crystallinity | Amorphous magnesium stearate has poorer lubricating properties than crystalline stearate. |

Flow Enhancement Properties

Magnesium stearate is hypothesized to improve powder flowability by forming a monomolecular film covering the surface of particles or by the layers of magnesium stearate particles filling the cavities in the matrix before forming a continuous layer. This would improve flow by minimizing any surface irregularities of the excipients, which reduces contact points between excipients, decreasing friction and cohesive forces as the particles became more spherical with a smoother surface morphology, which lowered the frictional forces by reducing contact points.

In a study, calcium stearate did not seem to fill surface voids preferentially. Excess calcium stearate decreased overall flow since the excess lubricant increased surface irregularities on the spray-dried lactose.

The amount of moisture affects the properties of the solids. Properties such as flow, compaction, disintegration, dissolution, hardness, and chemical stability are all influenced by moisture. Most studies show a decrease in powder flow with increasing moisture. One study revealed that the material’s flowability decreased with increased moisture content based on very high values for Hausner’s ratio, Carr’s Index, and angle of repose.

Effects on Product Properties

| Flowability of Powder | The flowability of powders is increased with the use of stearates. In a study, calcium stearate improved the flow properties of cornmeal at a concentration of just 0.5 % w/w. |

| Crystallization Tendency | Another study showed that calcium stearate inhibited recrystallization and the collapse of the structure of amorphous honey powder. |

| Release Properties and Dissolution Rate of Tablets | Pharmaceutical and nutraceutical tablet formulations use stearates as excipients. Magnesium stearate can form films on tablets, leading to prolonged liberation time, decreased hardness, and increased disintegration time. Because magnesium stearate is hydrophobic, it also affects the dissolution of matrix coated by causing slower wettability. |

| Emulsion Stability | In a study, Pickering emulsions were formed with the use of magnesium stearate. |

Safety and Regulatory Considerations

| FDA Information | The FDA lists Calcium and magnesium stearate as direct food substances and affirms them as “generally recognized as safe” (GRAS). Zinc stearate is listed as a nutrient/dietary supplement for zinc. Usage is not to exceed current good manufacturing practices. Aluminum and potassium stearate are listed as secondary direct food additives and can be used as defoaming agents in sugar processing and yeast. |

| EU Information | Stearates are permitted food additives as salts of fatty acids listed with E numbers E 470a and 470b. |

Health Effects of Stearates

Upon ingestion, magnesium stearate is dissolved into magnesium ions and stearic and palmitic acids. Magnesium is absorbed primarily in the small intestine and, to a lesser extent, in the colon. Magnesium is an essential mineral, serving as a cofactor for hundreds of enzymatic reactions, and is essential for synthesizing carbohydrates, lipids, nucleic acids, and proteins, as well as neuromuscular and cardiovascular functions.

Safety & Toxicity of Stearates

Magnesium and calcium stearates are generally recognized as safe to consume. However, there is no available information regarding their potential to induce genetic toxicity.

Identification Numbers

| Name | Magnesium Stearate | Calcium Stearate |

| CAS Number | 557-04-0 | 1592-23-0 |

| IUPAC Name | Magnesium; Octadecenoate | Calcium; Octadecenoate |

| EC Number | 209-150-3 | 216-472-8 |

| INS No. (Food Additive) | INS 470 (ii) | INS 470 (i) |

| E Number (Food Additive) | E 470b | E 470a |

Acceptable Limits or Maximum Usage

The Scientific Committee on Food (SCF) has not specified a group acceptable daily intake (ADI) for the following fatty acids: myristic‐, stearic‐, palmitic‐ and oleic acids or their salts.

Stearates are permitted by the EU to be used in the following categories with maximum permitted usage as given below:

| Compound(s) | Food Category | Maximum Level |

| Magnesium Stearate | Table-top sweeteners in tablets | Quantum satis |

| Sodium, Potassium, and Calcium Stearate | Table-top sweeteners in tablets | Quantum satis |

| Sodium, Potassium, and Calcium Stearate | Herbs and spices (Dried) | Quantum satis |

Fun Facts About Stearates

- Stearates are generally considered biodegradable, which means natural processes can break them down over time.

- Besides calcium and magnesium stearate, metallic stearates can be derived from various metals. These compounds find use in industries like plastics, rubber, and textiles.