Guar gum, or guaran, is a substance extracted from guar beans that has found its way into many natural food products. The gum’s ability to stabilize and thicken foods has made it a choice additive for many formulators. Typically used in baked goods, dairy products, condiments, and packaged food, this versatile ingredient provides a wide range of benefits beyond its primary functions because it’s a natural gluten and fat replacer. In this article, we’ll review the chemical properties of guar gum, some typical formulations, considerations, and safety and regulatory information.

What is Guar Gum?

Guar gum is an exo-polysaccharide consisting of mannose and galactose monomer units. It is a type of galactomannan. These sugars are linked together through glycosidic bonds, forming a complex polymer. The molecular weight of guar gum can vary depending on the processing method, but it typically ranges from 200,000 to 2,000,000 Daltons.

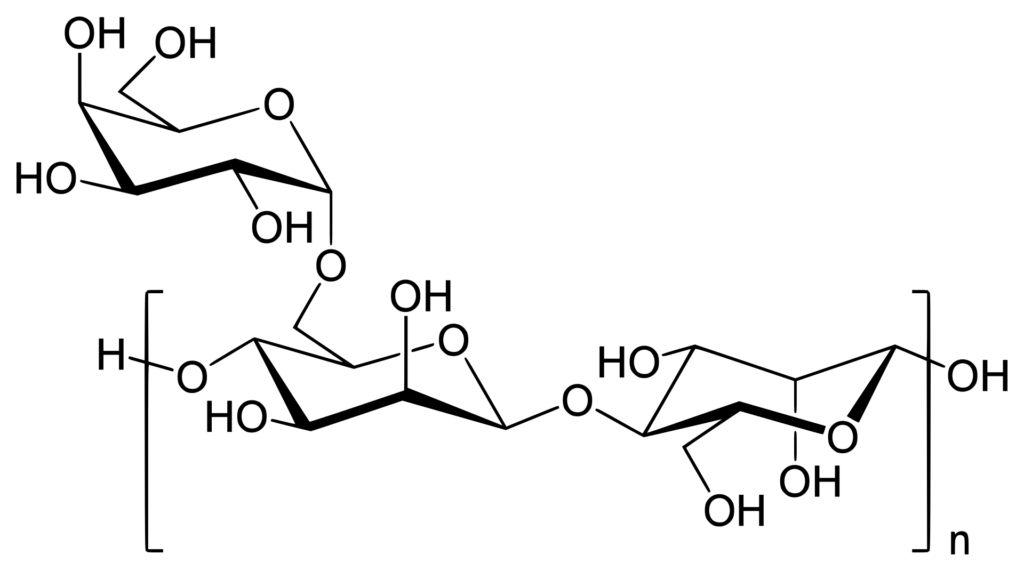

Source: Wikipedia

Here is the chemical structure of guar gum. Mannose forms the polymer backbone linked by β (1→4) glycosidic bonds. Galactose forms branches onto the mannose backbone through α (1→6) glycosidic bonds. The mannose-to-galactose ratio of guar gum has been reported to be approximately 2:1 [1]. The molecular weight of guar gum can range between 1-2 million Da. Guar gum produces very viscous solutions with water because of very good hydrogen bonding and extensive intermolecular entanglement.

How is Guar Gum Produced?

Guar gum is produced from the seeds of the guar plant (Cyamopsis tetragonoloba). Producing guar gum involves drying the seeds and mechanical dehusking to remove the outer shell to obtain the endosperm. Endosperm is ground and hydrated to form a slurry subjected to further purification and precipitation of gum. The dried guar gum is then milled into a fine powder for various applications [2].

Use of Guar Gum in the Food Industry

Here’s a breakdown of the functions of guar gum when used in food products:

| Function | Details |

| Thickener | Guar gum can increase the viscosity of liquids, making them thicker and more gel-like. |

| Emulsifier | Guar gum can act as an emulsifier, helping blend and stabilize oil- and water-based ingredients that normally separate. |

| Texturizer | Guar gum can improve the texture of food products by providing a smooth and creamy mouthfeel. It can also prevent the formation of ice crystals in frozen desserts, resulting in a smoother texture. |

| Stabilizer | Guar gum helps to prevent the separation of ingredients in food products, especially those with a high water content. It helps to maintain the uniformity and consistency of products. |

| Fat replacer | Guar gum can reduce the fat in certain foods, such as low-fat or reduced-calorie versions. |

| Gluten replacer | Guar gum is often used as a substitute for gluten in gluten-free baking. It helps to bind ingredients together and provide structure to baked goods. |

| Cryoprotectant | Guar gum helps prevent large ice crystals from forming during freezing. It stabilizes by binding water molecules and creating a gel-like structure. |

| Prebiotic | Guar gum may act as a prebiotic by promoting the growth of good bacteria and reducing harmful bacteria in the gut. |

Product Examples

Guar gum is typically used in the following food products:

| Type | Examples |

| Frozen foods | Ice cream, Frozen desserts, RTE gravies, Frozen soups |

| Bakery | Cake, Cookies, Pastries, Bread |

| Dairy | Yogurt, Cheese, Milk based desserts |

| Meat | Processed meats- Sausages, hot dogs |

| Beverages | Fruit juices, Nectars, Milk based beverages, Flavored beverages |

| Snacks | Chips, Crackers |

| Convenience | Dips, Gravies, Protein Bars, Dressings |

Apart from the above, the following specialty applications use guar gums due to their functional advantages.

- Gluten-free foods: Bread, Cakes, Cookies

- Low-fat foods: Yogurt, Cheese analogs, Dressings

- Vegan meat analogs: Vegan meat, Vegan fish analogs, Cheese analogs

Properties of Guar Gum

| Physical Form | Powder |

| Color | Yellow to white |

| Odor | Odorless |

| Storage Temperature & Conditions | Ambient conditions away from moisture |

| Molecular Weight | Variable, 50,000–8,000,000 |

| Appearance | Free flowing powder |

| pH | 6.5-7.5 |

| Density @ 25 °C | 0.8-1.0 g/mL |

| Viscosity (1 %, H2O, 20 ℃) | 350 to 700 mPa-s |

| Gelling Temperature | 25–40 °C |

| Melting Point | >220°C |

| Solubility | Highly soluble in water |

| Claims (*Product Specific) | Natural*, Halal*, Kosher*, Gluten-free, Non-GMO, Vegan, Plant-based, No added sugar |

Typical Formulations

Low-fat Meat Emulsion

| Ingredient | Weight Composition (g) |

| Sheep meat | 672 |

| Mutton fat | 100 |

| Ice water | 190 |

| Guar gum | 5 |

| Xanthan gum | 5 |

| Salt | 25 |

| Cardamom seeds | 2 |

| Cumin | 1 |

Partial replacement of fat in the meat emulsion was achieved by using a gum mixture to develop healthier restructured meat products with reduced fat content.

Source: NIH

Ice Cream

| Ingredient | Weight Composition (g) |

| Citric acid | 13.5 |

| Carob gum | 1.8 |

| Guar gum | 15 |

| Redisol | 4.5 |

| Skimmed milk powder | 10.5 |

| Sugar | 485.0 |

| Color | 3.5 |

| Strawberry flavor | 4.5 |

| Milk | 3000 ml |

Guar gum was used in the formulation to provide thickening and stability. The combination of guar and carob gum is especially preferred because of the synergistic effect on the longer stability of the final ice cream product.

Source: Google Patents

Gluten-free Bread

| Ingredient | Weight Composition (%) |

| Rice flour | 50 |

| Maize flour | 30 |

| Quinoa flour | 20 |

| Sunflower oil | 6 (flour basis) |

| White sugar | 3 (flour basis) |

| Refined salt | 1.5 (flour basis) |

| Instant yeast | 3 (flour basis) |

| Guar gum | 2.5 (flour basis) |

| Water | 100 (flour basis) |

The use of guar gum produces less sticky batters of increased firmness, work of adhesion, consistency, and viscosity index, which settle into baked loaves of reduced specific volume with a more cohesive, springy, adhesive, chewy, resilient, and firm crumb texture.

Source: Springer

Guar Gum Formulation Considerations

| Nutritional Profile | ~3 Cal/g |

| Sensory Attributes | Whitish and Yellowish color, Odorless with bland taste |

| Dosage | 0.05 to 1 %, depending on the intended application and effect |

Stability & Compatibility

Guar gum is heat stable and can be used in high-temperature processed food products. The first thermal event, around 300 °C, occurs with the loss of mass, which is related to the degradation of guar gum by the breakdown of the glycosidic bond [3]. However, the temperature stability is drastically reduced in low pH conditions [4]. It is stable to oxidation and light. It is hygroscopic and thus should be kept away from moisture.

Rheological Properties

Guar gum swells or dissolves in polar solvent on dispersion and forms strong hydrogen bonds. In nonpolar solvents, it forms only weak hydrogen bonds. It forms a viscous colloidal dispersion when completely hydrated, a thixotropic rheological system. Thixotropy denotes the reduction in resistance with an increased rate of shear. Dilute solutions are less thixotropic and become more thixotropic with increasing concentration.

Guar gum shows shear thinning behavior, also known as pseudoplastic. This means its viscosity decreases as the shear rate or shear stress increases. Once the shear force is removed, guar gum returns to its original viscosity. Guar gum aqueous solutions also do not show yield stress properties [5].

Factors Affecting the Functionality of Guar Gum

The rate of guar gum dissolution and viscosity development generally increases with decreasing particle size, decreasing pH, and increasing temperature. Hydration rates are reduced by dissolved salts and other water-binding agents, such as sucrose [6].

| Factor | Effect |

| Concentration | A doubling in the concentration of guar gum in solution leads to a tenfold increase in viscosity. Inter-molecular chain interaction or entanglement increases with concentration, leading to increased viscosity [7]. A low concentration of guar gum solutions shows Newtonian flow behavior, which over 0.5% changes to non-Newtonian and thixotropic behavior. Pseudoplastic flow behavior is reported in aqueous solutions containing 0.5%–1.5% of guar gum. At 1% concentration, the guar gum solutions show typical behavior of macromolecular biopolymer with dominating loss modulus (G″) over storage modulus (G′) in the lower frequency range [8]. |

| pH | Guar gum, being non-ionic, makes stable solutions over a wide pH range of about 1.0–10.5 in ambient conditions. At higher temperatures (>50 °C), the acid hydrolysis of guar gum was reported to be more prominent. The decrement in viscosity due to an increase in temperature was more prominent (4-23%) in highly acidic conditions (pH 1-3) [9]. The rate of hydration is also affected by the pH. |

| Temperature | At a constant shear rate, the viscosity of 1% guar gum solution decreased with increased temperature. Also, at an increasing shear rate, the decrease in viscosity was accelerated by a rise in temperature. Temperature rise induced kinetic movement, leading to more vibrations and thus loosening the intermolecular forces, causing a rapid decrease in viscosity [10]. |

| Mixing time | At a constant shear rate, mixing time did not significantly impact the viscosity of the guar gum solution [11]. |

| Shear Rate | A study reports that 1 % guar gum solution decreases viscosity with increased shear. The drastic decrease in viscosity at higher shear rates can be attributed to the rapid rupture of the polymer chain arrangement [10]. |

| Storage time | With time, guar gum aqueous solutions show a decrease in storage modulus (G′) and loss modulus (G″) [12]. |

| Salt | Salt affects the electrostatic interactions in a solution. Gum solution containing no salt exhibits high viscosity due to highly expanded molecules in the medium [13]. The effect of salt concentration was reported to be concentration-dependent. Viscosity was slightly lower for 0.2% guar gum solution with increasing salt concentration. Below 0.2% guar gum, the solution did not show a significant effect [14]. The viscosity of guar gum solution reportedly declined as the shear rate increased with rising salt concentration [13]. |

| Sugar | The presence of sugar in guar gum solution causes a delay in the hydration of guar gum molecules [15]. |

Physical treatments

| Factor | Effect |

| Micronization | The surface of guar gum became loose and rough after micronization, indicating a major disruption of the microstructure of guar gum. It resulted in a reduction (~100 folds) in the viscosity of guar gum solution compared to the untreated sample [16]. |

| Sonication | Sonication alters the rheological properties where a reduction in apparent viscosity was observed along with a transition into Newtonian flow behavior. Such changes may be due to the irreversible permanent pyrolysis of hydrocolloid dispersions [17]. Sonication affected the consistency index (k), flow behavior index (n), and complex power law constants. |

| Radiation | Radiation is a dry technique for depolymerization that does not require making a guar gum solution. Radion of 20-50 KGy is reported to reduce the viscosity of 1% guar gum solution from 10000 cps to up to 1 cps [18]. |

Intrinsic Properties

| Property | Effect |

| Particle size & shape | The shape and size of particles had a major impact on the hydration of guar gum [19]. Increased particle size caused a decrease in apparent viscosity and an increase in the flow index of guar gum samples [20]. |

| Chain length (Molecular weight) | The shear thinning behavior of guar gum increases with molecular weight. The intrinsic viscosity of guar gum is directly correlated to the molecular weight [21]. |

| Modification | The flow properties of polymers are altered by substitution in important and unexpected ways. Some of the characteristics are as given below. |

Modified Guar Gum

The substitution of the hydrophobic hydroxypropyl group on guar gum decreases the zero-shear rate value and relaxation time compared to native guar gum. Meanwhile, for hydrophilic substitution with the sodium carboxymethyl group, the viscosity at lower concentrations is higher than native guar gum [22]. This can be due to the electro-viscous effect of polyelectrolytes. Similarly, hydroxyethyl guar gum had lower viscosities than native guar gum [23].

Modification of guar gum with unsaturated fatty acids gives oleic guar gum (OGG), linoleic guar gum (LGG), and erucic guar gum (EGG). They showed stronger shear thinning properties at a concentration of 1% compared to native guar gum. The molar substitution ratio for these groups also affects the rheological properties [24].

Guar Gum Derivatives

Guar gum hydrolysates can be obtained by either acid/ base hydrolysis or enzyme-mediated hydrolysis. Acid hydrolysis yields samples of various molecular weights with uniform polydispersity. This contrasts with preparation by enzymatic degradation that yields samples with a marked increase in polydispersity and a much broader molecular weight distribution [25].

A huge difference between the viscosity of native and partially hydrolyzed guar gum can be observed (~100-fold decrease) [26]. Hydrolysis leads to the breaking of the galactomannan chain and yields shorter-length chains, which justifies this behavior. Hydrolysis significantly affected the solution’s rheological properties, leading to an almost Newtonian behavior at lower concentrations [26]. The Huggins coefficient for hydrolyzed guars is much smaller than in native guar, suggesting a weakening intermolecular association prepared by hydrolysis [27].

Effect on Properties of Food Products

| Effect | Details |

| Consistency | Guar gum has excellent water-binding properties, which allows it to thicken the consistency of food products. It can increase the viscosity of liquids, making them more gel-like or creamy. Guar gum acts as a binder in food products, helping to hold ingredients together. |

| Mouthfeel | Guar gum improves the viscosity of liquid food products thus helping to get a fuller and richer mouthfeel. It can improve solid and semi-solid foods’ cohesiveness, gumminess, and fracture properties [28]. Guar gum can imitate the mouthfeel of fat globules, making it an excellent fat replacer [29]. |

| Moisture content | Incorporating guar gum increases dough’s water absorption capacity and improves food products’ moisture retention. The moisture retention of bread is improved significantly (~10% more than control) using guar gum [30]. Reduced retrogradation is one of the most prominent moisture retention effects [31]. Guar gum also caused a decrease in dough development time, increased gluten development, dough stability, breakdown time, and mixing tolerance index [32]. |

| Oil content | Guar gum can act as a fat replacer. Partial fat replacement with guar gum resulted in higher emulsion stability and cooking yield but lower penetration force in meat emulsions [33]. Guar gum can also help reduce the oil content of food by reducing the oil uptake while frying. Coating with guar gum has reported a ~54% reduction in the oil uptake of potato chips [34]. |

| Texture | Guar gum improves the final product’s texture and structure in gluten-free baking. It provides the necessary binding properties absent in gluten-free flours, resulting in a more elastic and cohesive dough. Guar gum increased the volume and porosity and reduced the firmness of bread comparatively [35]. |

| Freeze thaw stability | Guar gum can prevent the formation of ice crystals during freezing, which may lead to a loss of moisture and a deterioration in the quality of the product upon thawing. It is widely used in ice creams to improve frozen products’ stability and mouth feel [36]. |

| Calorie content | Guar gum can effectively act as a thickener, stabilizer, and emulsifier. The required dosage of guar gum is significantly lower than that of some stabilizers like maltodextrin and starches. It helps in reducing the overall caloric output of the food. |

| Taste | Guar gum has a bland taste with slightly bitter notes. However, the required dosage is small. Thus, the overall effect on the final product’s taste may be insignificant. |

| Flavor release | Guar gum can alter a food’s flavor delivery speed and extent. Above a critical concentration of guar gum in the food system, flavor perception may be reduced due to the inhibition of the transport of flavor molecules to the surface by the entangled network [37]. |

Interaction with Other Components

Guar gum can interact with proteins in food, forming complexes that can affect the texture and stability of the product. It can bind to proteins and create a network that helps to improve the texture and mouthfeel of food products, such as dairy-based desserts.

Comparison with Other Hydrocolloids

Hydrocolloids are a heterogeneous group of long-chain polymers (polysaccharides and proteins) characterized by their property of forming viscous dispersions and/or gels when dispersed in water. The presence of many hydroxyl (-OH) groups markedly increases their affinity for binding water molecules, rendering them hydrophilic compounds. Despite its higher molecular weight, guar gum has relatively lower activation energy and is thermally more susceptible than other gums like locust bean gum [38].

The table below compares typical properties and applications of some commonly used thickening hydrocolloids [39].

| Hydrocolloid as a thickener | Properties | Application in food products |

| Galactomannans (Guar gum, Locust bean gum, and Tara gum) | Very high low-shear viscosity; highly shear thinning; independent of electrolytes but degrade and lose viscosity at high and low pHs and at high temperatures | Dairy products including ice cream, ketchup, fruit juices, pudding powder, cake batter |

| Xanthan gum | Highly shear thinning; maintains viscosity in the presence of electrolytes, high temperature and wide pH ranges | Soups and gravies, ketchup, instant beverages, desserts, toppings, and fillings |

| Carboxymethyl cellulose (CMC) | High viscosity but is reduced by adding electrolytes and at low pH | Salad dressings, gravies, fruit pie fillings, ketchup |

| Methyl cellulose (MC) and hydroxypropyl methyl cellulose (HPMC) | Viscosity increases with temperature but independent of pH and electrolytes | Salad dressings, cake batters, beverages, whipped toppings |

| Gum Arabic | Low viscosity gum; shear thinning at low shear rates (<10/sec); near Newtonian behavior above 100/sec of shear rate | Fruit juice-based beverage, soft drinks |

| Konjac mannan | Forms highly viscous dispersions which are not influenced by addition of salts; forms thermally irreversible gels with alkali | Noodles and jelly desserts |

| Gum Tragacanth | Swells rapidly in cold or hot water to form highly viscous dispersions, up to 4000 mPas at 1% solids | Salad dressings, bakery emulsions, fruit beverages, sauces |

Benefits of using Guar Gum in Food Applications

- The main advantages of using guar are its low cost, easy availability, and capacity to form viscous solutions and gels at low concentrations.

- Cold swelling: A significant characteristic of guar gum is its ability to hydrate rapidly in cold water systems to give highly viscous solutions.

- Shear thinning behavior: When a force is applied to guar gum, such as stirring or pumping, it thins out and flows more easily. This property benefits food applications by allowing easier mixing and processing while providing the desired thickening and stabilizing effects at rest.

- Low dosage requirement: A significant increase in viscosity of the aqueous solution is reported even at relatively low amounts of added guar gum to the water. Hence, it is recommended to be below 1% concentration in most food applications. Thus, it does not significantly affect the taste of food.

Synergistic Use

In various food applications, Guar gum can form synergistic gels with biopolymers such as xanthan and carrageenan. Combining guar gum and xanthan gum creates a stronger, more elastic, and more viscous solution than each separately. Also, studies have shown that the formed gel is stronger, and its resistance to shear forces increases, which can be used in products such as salad dressings, sauces, and drinks [40]. Guar gum has synergistic effects with locust bean gum and sodium alginate.

Safety and Regulatory Considerations

| FDA Information | Guar gum is the natural substance obtained from the maceration of the seed of the guar plant. It is “generally regarded as safe” (GRAS) as per the US FDA [41]. |

| EU Information | Guar gum (E 412) is a permitted food additive as per the Commission Regulation (EU) No 1129/2011 [42]. |

Health Effects of Guar Gum

| Health Benefit | Details |

| Cardiovascular health | Guar gum decreases total cholesterol and LDL-cholesterol, which may promote lipid health and prevent cardiovascular diseases [43]. |

| Digestive health | Partially hydrolyzed guar can be considered as a potential prebiotic composite that may further encourage the growth of potentially probiotic bacteria or native gut microflora [44]. It also helps accelerate colon transit time in patients with chronic constipation [45]. Partially hydrolyzed guar gum consumption was also associated with improvements in stool texture and bowel movement frequency. |

| Diabetes | The partially hydrolyzed guar gum intake reduces the postprandial blood glucose absorption in the small intestine and glucose level in systemic circulation [46]. |

| Weight management | Due to the gel-forming capacity of guar gum soluble fiber, increased satiation is achieved because of slow gastric emptying [47]. |

Safety & Toxicity of Guar Gum

Guar gum is generally considered safe for consumption. It is approved by regulatory authorities such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

However, like any substance, guar gum can cause adverse effects in some individuals, especially when consumed in large amounts. Some people may experience digestive issues such as bloating, gas, and diarrhea when consuming guar gum. These effects are generally mild and temporary.

Identification Numbers

| CAS Number | 9000-30-0 |

| EC Number | 232-536-8 |

| EIENCS Name | 232-536-0 |

| INS No. (Food Additive) | INS 412 |

| E Number (Food Additive) | E 412 |

| FEMA Number | 2537 |

Acceptable Limits or Maximum Usage

The acceptable daily intake (ADI) for guar gum is “not specified” as per the JECFA [48].

The maximum usage level of Guar Gum in the food industry} per the US FDA is as follows [49].

| Food (as served) | Percent |

| Baked goods and baking mixes | 0.35 |

| Breakfast cereals | 1.2 |

| Cheese | 0.8 |

| Dairy products analogs | 1 |

| Fats and oils | 2 |

| Gravies and sauces | 1.2 |

| Jams and jellies, commercial | 1 |

| Milk products | 0.6 |

| Processed vegetables and vegetable juices | 2 |

| Soups and soup mixes | 0.8 |

| Sweet sauces, toppings and syrups | 1 |

| All other food categories | 0.5 |

In the EU, guar gum as a food additive is permitted in the following categories. The maximum usage level of guar gum per the EU for different food categories is below [50].

| Category | Maximum Limit |

| Unflavored live fermented cream products | Quantum satis |

| Table-top sweeteners in liquid form | Quantum satis |

| Table-top sweeteners in powder form | Quantum satis |

| Canned or bottled fruit and vegetables | Quantum satis |

| Jam jellies and marmalades and similar products | 10000 mg/kg |

| Jam jellies and marmalades and similar products | 10000 mg/kg |

| Infant formulae | 1000 mg/kg |

| Follow-on formulae | 1000 mg/kg |

| Processed cereal-based foods and baby foods for infants | 10000 mg/kg |

| Other foods for young children | 10000 mg/kg |

| Dietary foods for infants for special medical purposes | 10000 mg/kg |

| Dietary foods for babies and young children | 10000 mg/kg |

| Meat preparations | Quantum satis |

Also, the permitted categories and maximum usage limits for guar gum prescribed as per the GSFA, Codex are given here.

Fun Facts About Guar Gum

- Various cultures have used guar gum for centuries, primarily in South Asia, where the guar beans are native.

- During World War II, guar gum was added to explosives to stabilize bombs.

- Guar beans grow in arid environments, making them a sustainable choice from a production perspective.

- One of guar gum’s primary industrial applications includes hydraulic fracturing for oil and gas production. It assists in the delivery of proppants into rock fractures.

- Eating guar gum creates a sense of fullness, and it’s been suggested it might be effective for foods intended to help with weight loss.

- Guar meal, a byproduct of guar gum, is used in feeds for livestock.

- In Ayurvedic medicine, the traditional medicine of India, guar gum has been used to treat various health issues like diabetes, constipation, and high cholesterol.